The challenges of retrofits.

Each ballast water treatment system and scrubber retrofit is a complicated process requiring careful and thorough planning.

In 2019 Thenamaris initiated a project to retrofit ballast water treatment systems (BWTS) and scrubbers on vessels of the managed fleet to comply with International Maritime Organization (IMO) requirements. According to the Ballast Water Management (BWM) Convention, which entered into force in 2017, vessels must install a ballast water treatment system to prevent the spread of harmful marine organisms from one region to another, and stop damage to the marine environment from ballast water discharge.

On January 1, 2020, a new limit on the sulphur content in the fuel oil used on board ships also came into force. This means that vessels must use fuel oil that is low enough in sulphur to meet the regulations, or install an exhaust gas cleaning system also known as a ‘scrubber’.

Each BWTS and scrubber retrofit is a complicated process requiring careful and thorough planning. The process begins with the Thenamaris Technical department providing technical data and specifications to various suppliers. Based on the quotes from the suppliers who comply with the specifications, the Purchasing department assesses the potential options based on a number of criteria including estimated retrofit cost, operational cost, availability and delivery times, after-sales service, and, if available, historical information about the supplier. After carefully considering the various criteria, the selection is made and an order placed for the manufacturing of the equipment and the provision of the necessary materials. Once ready, the equipment and materials must be delivered to the nominated shipyard where the vessel will be retrofitted. Typically retrofits are undertaken during regularly scheduled dry dockings when other maintenance and repair work also takes place.

To prepare for the retrofit an engineering plan and detailed drawings of the systems are prepared by a technical bureau, a company specializing in the BWTS or scrubber retrofits, and submitted to the relevant classification society to receive plan approval. A classification society is an independent, non-governmental organization that develops technical standards for the design, construction and maintenance of ships and vital equipment, and ensures the ship complies with all applicable rules and regulations. It is a requirement to involve the classification society in any retrofit plan approval.

Once approved, the engineering plan and drawings are forwarded to the shipyard for the prefabrication to commence. Prefabrication refers to the assembly of components before they are transported to the vessel. The prefabrication work for such retrofit projects usually takes 30 to 40 days. In addition to the prefabricated assemblies, other pieces of equipment, referred to as makers’ equipment, are assembled with the prefabricated components during the vessel’s stay at the shipyard. A maker is a manufacturer of the individual pieces of equipment, such as scrubbers, pumps or instruments.

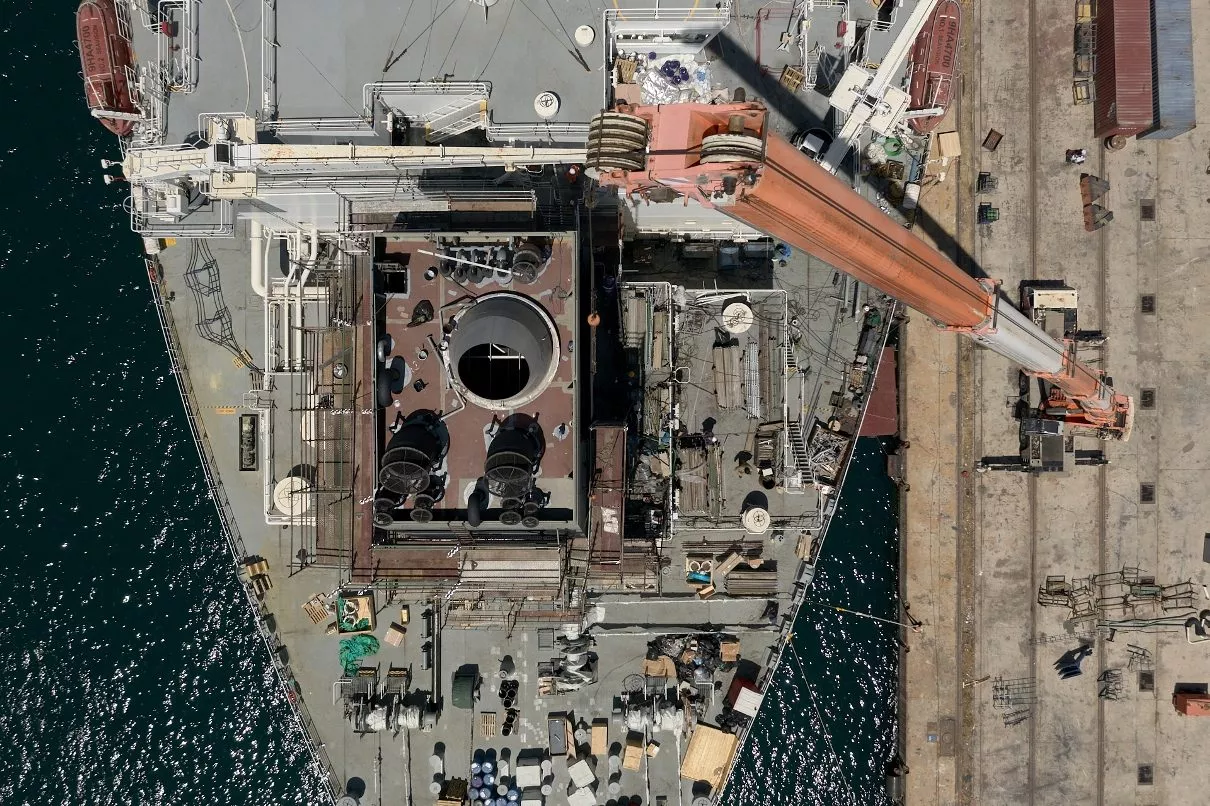

In the case of scrubber retrofits, due to the dimensions and weight of the manufactured equipment and parts, a special boat must be arranged to transfer the prefabricated assemblies and other equipment on to the vessel. A fully-assembled scrubber can weigh up to 40 tons, and extensive modification and sometimes even enlargement of the engine funnel is required to accommodate the retrofit. Whereas BWTS retrofits do not entail such large and heavy parts, the number of parts that need to be assembled on board is in the hundreds.

Once everything is on board the shipyard marine chemists must check the atmosphere in the area prior to any ‘hot work’ taking place. Hot work is any work that requires the application of heat or that generates extreme heat, such as welding, grinding and brazing. Then, the makers’ service technicians commence with the installations.

Upon completion of all installations, as well as testing and commissioning by the makers’ service team, the classification society surveyor verifies the installation and ensures that all safety requirements have been met. The surveyor also witnesses the operation of the retrofit during sea trials, and certifies that everything is in line with class rules and regulations.

Retrofit projects are very demanding by nature. Vasilis Valsamis, Project Manager in the Thenamaris Technical department responsible for the BWTS and scrubber retrofits, explains, “Each and every retrofit project is different and complex. The particular characteristics of each vessel must be meticulously considered, and the new equipment installed on board in the most optimal way. Careful planning and excellent communication between the multiple parties involved is necessary to ensure the project is completed efficiently and effectively, enabling the vessel to return to the seas as soon as possible.”